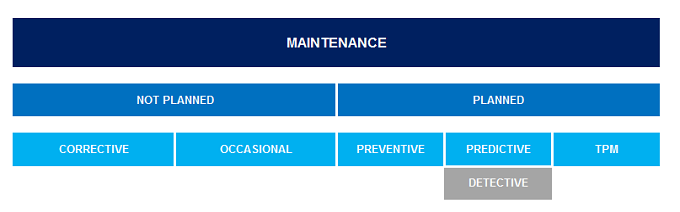

MAINTENANCE NOT PLANNED

Corrective

Corrective maintenance is the most obvious and most primary form of maintenance; it can be synthesized by the “break-repair” cycle, that is, the repair of the equipment after the breakdown. Constitute the most expensive form of maintenance when viewed from the total point of view of the system.

OCCASIONAL

It is the one where basic procedures, minor repairs, modifications for improvements or performance adjustments are made, this is when the machine is off, such as at production intervals, lunch breaks or between shifts, and do not follow a specific routine, therefore, they are occasional.

PLANNED MAINTENANCE

Preventive

Preventive Maintenance, as its name suggests, consists of a work to prevent defects that may cause the stoppage or a low performance of the equipment in operation. This prevention is based on statistical studies, equipment status, installation location, mechanical conditions that supply it, data provided by the manufacturer (optimal operating conditions, lubrication points and periodicity, etc.), among others.

Predictive

The purpose of this type of maintenance is to prevent failures in equipment or systems by monitoring its diverse geometry, allowing the continuous operation of the equipment for as long as possible. It is the first major paradigm shift in maintenance, and the more it intensifies the more technological knowledge develops equipment that allows reliable assessment of the installations and operating systems in operation.

Detective

Detective maintenance is the performance performed in protection systems seeking to detect hidden flaws or not perceptible to the operation and maintenance personnel.

TPM

Total Productive Maintenance (TPM) or Total Productive Maintenance, is a system developed in order to eliminate losses, reduce downtime, guarantee quality and reduce costs in companies with continuous processes. These are improvements aimed at intervention in the production process, with the aim of improving the effectiveness of the installation. It takes care to incorporate and develop a process of continuous improvement, seeking to eliminate the great losses caused in the production process. More information please contact us.